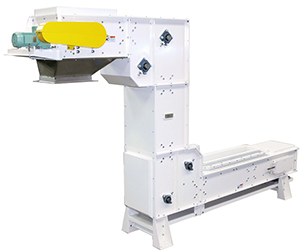

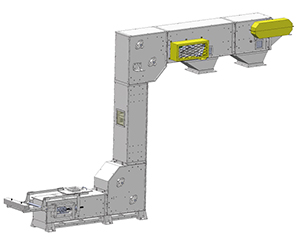

The bucket conveyor combines three transport stages-horizontal, vertical and horizontal again-in a single unit. Showa has been supplying pivoted bucket conveyors for powders and solids for more than 40 years. Drawing on our extensive experience and expertise, we offer a wide variety of models to suit every application, from standard specifications through to custom options.

Typical applications

Food: Candies, coffee beans, soy beans

Chemical: Carbon, granulated agrochemicals, sealant

Biomass/environmental materials: granulated paper sludge, wood pellets, granulated sludge

Feed and fertilizers: compound fertilizers, fish farming pellets

Other: Glass, coins, lime powder

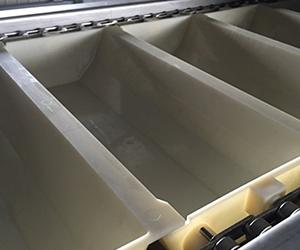

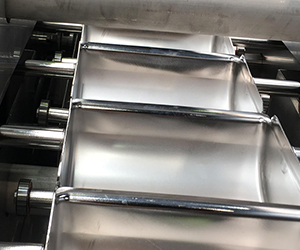

Inverted return

Buckets are inverted for the return journey after the load is delivered. This minimizes contamination with impurities and keeps the buckets stable between the guides.

SPL pivoted bucket conveyor

Continuous overlapping type

Models

Bucket sizes: 15 - 36 inch

Capacity (at 50% loading): 16 - 38.4 m3/h

SPM pivoted bucket conveyor

Continuous overlapping type

Models

Bucket sizes: 9 - 18 inch

Capacity (at 50% loading): 7.8 - 15.0 m3/h

SPS pivoted bucket conveyor

Continuous overlapping type

Models

Bucket sizes: 6 - 15 inch

Capacity (at 50% loading): 2.9 - 7.4 m3/h

SPSS-6 mini pivoted bucket conveyor

Continuous overlapping type

Capacity (at 50% loading): 2.4 m3/h

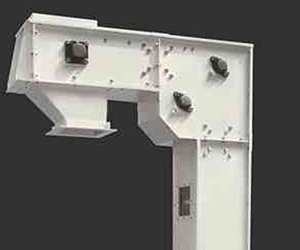

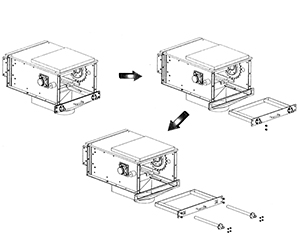

Upright return

Buckets remain in upright orientation at all times, to make it easier to deal with spills and splashes.

Intermediate discharge outlets can be located directly beneath the machine to save space and facilitate the design layout.

SPS-U pivoted bucket conveyor

Continuous overlapping type

Models

Bucket sizes: 160, 250 and 330 mm

Capacity (at 60% loading): 2.9 - 6.0 m3/h

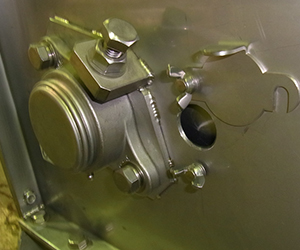

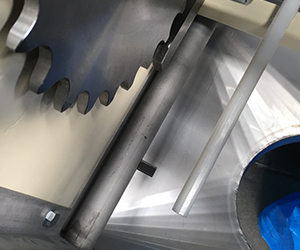

Pivoted bucket conveyor contamination

Preventing contamination of transported materials

Rotating and sliding components of machinery are subject to friction and wear. This can produce dust particulates, while other foreign matter may also be present on machine parts.

To reduce the risk of contamination, it is important to understand how contaminants are generated so we can minimize at the source.

At Showa, we have used our extensive experience and expertise in transport systems to introduce a range of design innovations to minimize contamination, including machine design, material selection and heat treatment, and enclosures.

We also offer additional contamination minimization options customized to specific operational settings.

Typical installations

Food

| Alpha rice | Almonds | Azuki beans | Amino acids | Candies | Kidney beans |

| Tea | Dried seaweed products | Cacao nibs | Cacao beans | Fish flakes (katsuobushi) | Chewing gum |

| Soybean flour | Caramels | Gummy sweets | Black soybeans | Ground coffee | Coffee beans |

| Cornflakes | Sesame seeds | Rice | Sugar | Breakfast cereals | Soybeans |

| Leaf tea | Chocolate | Granulated starch | Corn | Breadcrumbs | Peanuts |

| Pet food | Mung beans | Macaroni | Frozen potato chips |

Chemicals

| Acenaphthylene | Aluminum chips | Alumina granules | Epoxy resins | Lead balls | Carbon |

| Caustic soda | Gunpowder | Zinc oxide | Titanium oxide | Molybdenum oxide | Unprocessed resins |

| Potassium nitrate | Aluminum hydroxide | Magnesium hydroxide | Soapmaking materials | Iron powder | Copper chips |

| Urea | Agrochemical powder mix | Agrochemical granules | Pitch pellets | Sealant | Phenol resins |

| Manganese powder | Mill scale | Iodine granules | Aluminum sulfate | Ammonium sulfate | Copper sulfate |

Biomass and environmental materials

| Granulated paper sludge | Char | Bark | Granulated biomass material | Carbonated biomass material | Pulp pellets |

| Woodchips | Wood pellets | Granulated sludge |

Feed and fertilizers

| Compound fertilizers | Granulated compound fertilizer | Fish meal | Soy sauce lees | Livestock feed | Synthetic milk |

| Corn | Fertilizer | Bran | Fish farming pellets |

Other

| RPF granules | Aluminum | Aluminum flakes | Casting sand | Carbon fiber | Activated charcoal |

| Activated clay | Glass | Glass wool | Glass fiber | Silica sand | Building materials |

| Abrasives | Coins | Coking powder | Rubber chips | Reconstituted sand | Burned ash |

| Slaked lime | Steel grids | Powdered slag | Lime powder | Plasterboard | Cement |

| Ceramic balls | Graded paper | Tires | Perlite | Ridging materials | Fine ceramic powder |

| Plastic bottle caps | Scallop shells | Compound furnace materials |

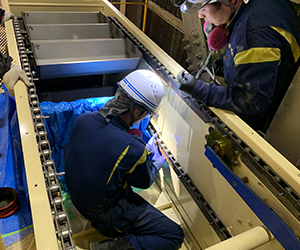

Maintenance and servicing

Showa offers fast and efficient maintenance and servicing. We service conveyors from manufacturers who have gone out of business, and also provide customization and modification services for conveyors from any manufacturer.

Pivoted bucket conveyors (Manufacturer and model)

Japan Pivot Conveyors, Pivostar Lift

Maruishi Sangyo, Pivoace Lift

Toyo Kosho, Pivobest

Flight conveyors (Manufacturer and model)

Escar, Flicker Conveyor

Kinryu Industrial Enterprise, Silent Veyor

Please inquire for maintenance, modification and replacement parts and components.

Showa boasts a full inventory of Pivocon and N-CON parts including chains, sprockets, buckets and flights.

Please inquire for details.